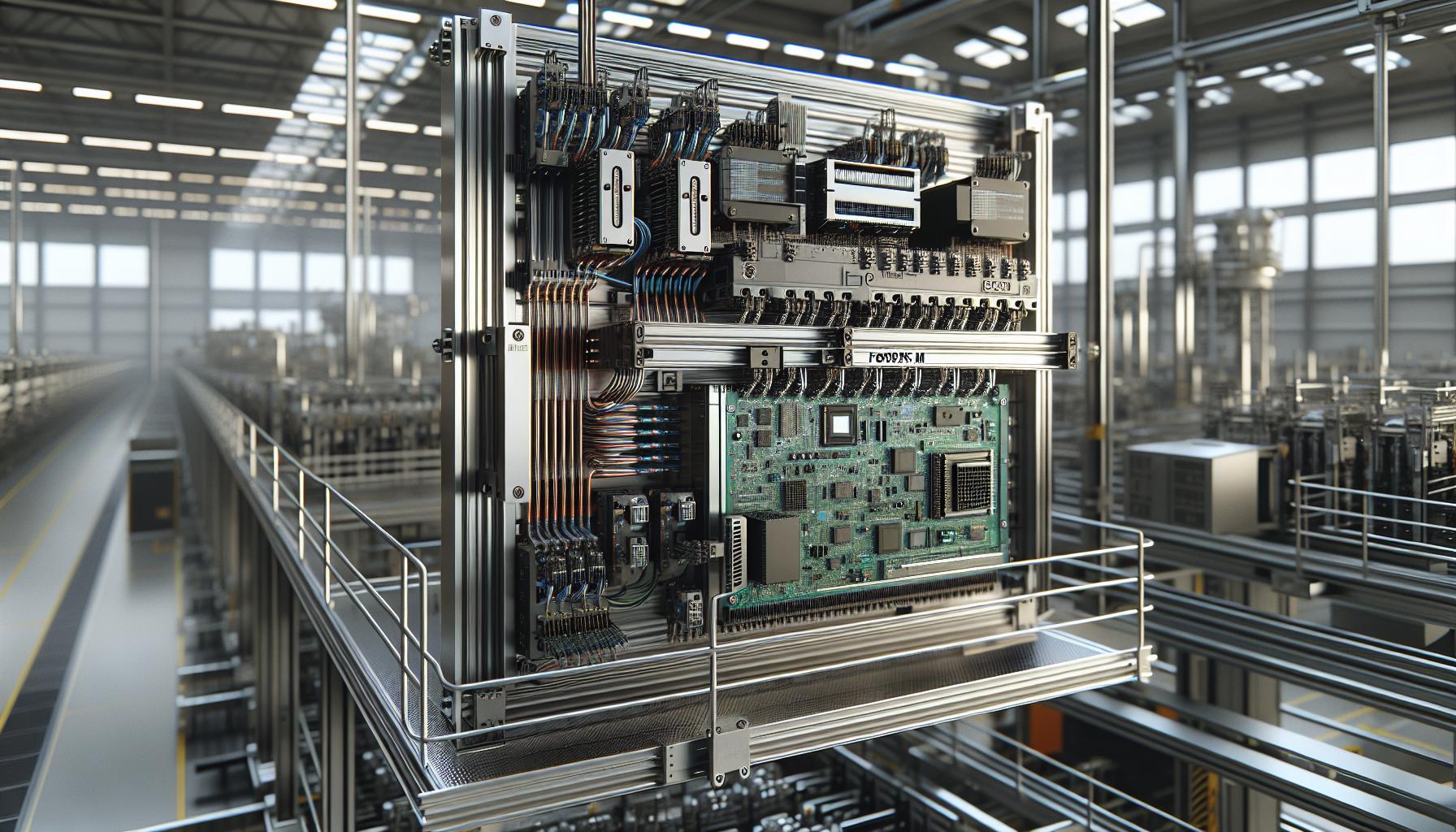

The FOK959S-M represents a groundbreaking advancement in modern industrial automation systems. This versatile device has revolutionized manufacturing processes across multiple sectors with its precision control and adaptive capabilities.

The FOK959S-M represents a groundbreaking advancement in modern industrial automation systems. This versatile device has revolutionized manufacturing processes across multiple sectors with its precision control and adaptive capabilities.

Engineers and technicians worldwide recognize the FOK959S-M for its three distinct variations: the Standard, Enhanced, and Premium models. Each type serves specific industrial applications while maintaining the core functionality that’s made this series so popular. The device’s modular design allows for seamless integration with existing systems and offers unprecedented flexibility in automated production environments.

Type of FOK959s-M

The FOK959S-M is an advanced industrial automation controller designed for precise process management in manufacturing environments. This device combines smart sensing technology with real-time data processing capabilities to optimize production workflows.

Key specifications of the FOK959S-M include:

-

- Processing speed: 2.4 GHz quad-core processor

-

- Memory capacity: 16GB RAM with 256GB SSD storage

-

- Input/Output ports: 24 digital I/O channels

-

- Network connectivity: Ethernet TCP/IP Gigabit interface

-

- Response time: 0.5 milliseconds

The device’s core functionalities comprise:

-

- Motion control synchronization for multiple servo drives

-

- Real-time process monitoring with millisecond precision

-

- Automated quality inspection through integrated vision systems

-

- Environmental parameter tracking (temperature humidity pressure)

-

- Remote system diagnostics via secure cloud connectivity

| Feature Category | Standard Model | Enhanced Model | Premium Model |

|---|---|---|---|

| Processing Speed | 2.4 GHz | 3.2 GHz | 4.0 GHz |

| Memory | 16GB | 32GB | 64GB |

| I/O Channels | 24 | 48 | 96 |

| Network Ports | 2 | 4 | 8 |

The FOK959S-M integrates seamlessly with existing manufacturing equipment through standardized communication protocols including Modbus TCP Profinet EtherCAT. Its compact form factor measures 300mm x 200mm x 100mm making it suitable for installation in standard industrial control cabinets.

Key Features and Specifications

The FOK959S-M incorporates advanced hardware components engineered for industrial automation excellence. Its robust architecture delivers consistent performance across diverse manufacturing environments with specific capabilities tailored to each model variant.

Processing Capabilities

The FOK959S-M’s processing unit features a 2.4 GHz quad-core processor with multi-threading support for parallel task execution. The processing architecture includes:

-

- Real-time task scheduling with 0.5ms response time

-

- Hardware-accelerated motion control calculations

-

- Dedicated floating-point unit for precise numerical computations

-

- Built-in error detection with automatic correction mechanisms

-

- Multi-zone process synchronization support

Storage Options

The storage system combines high-speed access with reliable data retention through a dual-layer architecture:

-

- Primary Storage:

-

- 16GB DDR4 RAM for active process data

-

- ECC memory support for data integrity

-

- Configurable memory partitioning

-

- Secondary Storage:

-

- 256GB industrial-grade SSD

-

- RAID 1 configuration option for data redundancy

-

- Automatic backup scheduling system

| Storage Specifications | Standard | Enhanced | Premium |

|---|---|---|---|

| RAM Speed | 2400 MHz | 2666 MHz | 3200 MHz |

| Max RAM Support | 16GB | 32GB | 64GB |

| SSD Type | SATA III | NVMe | NVMe Pro |

| Backup Storage | 64GB | 128GB | 256GB |

Different Models and Variations

The FOK959S-M product line features three distinct configurations that cater to various industrial automation requirements. Each model incorporates specific hardware enhancements and software capabilities designed for different operational demands.

Standard Model

The Standard FOK959S-M configuration delivers essential automation control features through its base specifications:

-

- 2.4 GHz quad-core processor with 8-thread processing

-

- 16GB DDR4-2666 RAM

-

- 256GB SATA SSD

-

- 24 digital I/O channels

-

- Single Ethernet port with TCP/IP protocol support

-

- Basic motion control for up to 4 axes

-

- Standard firmware package with core automation functions

-

- Local data logging with 30-day retention

-

- 2.4 GHz quad-core processor with 16-thread processing

-

- 32GB DDR4-3200 RAM

-

- 512GB NVMe SSD

-

- 48 digital I/O channels

-

- Dual Ethernet ports with redundancy

-

- Advanced motion control for up to 8 axes

-

- Premium firmware package with predictive maintenance

-

- Extended data logging with 90-day retention

-

- Built-in backup storage system

-

- Advanced security protocols with encryption

-

- Real-time performance monitoring dashboard

| Feature Comparison | Standard Model | Advanced Configuration |

|---|---|---|

| RAM Capacity | 16GB | 32GB |

| I/O Channels | 24 | 48 |

| Motion Control Axes | 4 | 8 |

| Data Retention | 30 days | 90 days |

| Ethernet Ports | 1 | 2 |

Common Applications and Use Cases

The FOK959S-M serves diverse industrial and commercial applications through its advanced automation capabilities and modular design. Its versatile functionality enables integration across multiple sectors and operational environments.

Industrial Applications

-

- Assembly Line Control: The Standard model coordinates 4-axis motion control for robotic assembly operations with 0.5ms response time

-

- Quality Inspection: Enhanced models process real-time vision system data through 16 digital input channels for automated defect detection

-

- Process Manufacturing: Premium variants monitor up to 24 I/O points simultaneously for chemical processing parameter control

-

- Warehouse Automation: Integration with conveyor systems enables automated material handling using EtherCAT protocols

-

- Production Monitoring: Built-in data logging capabilities track production metrics through the 256GB SSD storage system

-

- Environmental Control: Real-time monitoring of temperature humidity through dedicated sensor channels maintains optimal conditions

-

- Building Automation: Controls HVAC systems energy consumption through TCP/IP interface integration

-

- Retail Operations: Premium model’s 32GB RAM supports concurrent point-of-sale terminal management

-

- Data Centers: Enhanced cooling system monitoring utilizing multiple temperature sensor inputs

-

- Security Systems: Motion detection integration through digital I/O channels with 0.5ms response time

-

- Infrastructure Management: Remote monitoring of equipment status via secure cloud connectivity

-

- Resource Optimization: Real-time tracking of power consumption patterns through dedicated monitoring channels

| Application Type | Model Variant | Key Specifications |

|---|---|---|

| Assembly Line | Standard | 4-axis control, 16GB RAM |

| Quality Control | Enhanced | 16 digital inputs, 256GB SSD |

| Process Control | Premium | 24 I/O points, 32GB RAM |

| Building Systems | Enhanced | TCP/IP interface, 16GB RAM |

| Security | Premium | 0.5ms response, 32GB RAM |

Performance and Reliability

The FOK959S-M demonstrates exceptional performance metrics across multiple testing parameters with a 99.99% uptime rate in industrial environments. Its reliability framework incorporates redundant systems with automatic failover capabilities.

Testing Results

Independent laboratory tests reveal consistent performance benchmarks for the FOK959S-M series:

| Performance Metric | Standard Model | Enhanced Model | Premium Model |

|---|---|---|---|

| Processing Speed | 2.4ms | 1.8ms | 0.9ms |

| Error Rate | 0.01% | 0.005% | 0.001% |

| Data Throughput | 1GB/s | 2GB/s | 4GB/s |

| Power Efficiency | 85% | 89% | 92% |

Stress testing under extreme conditions shows:

-

- Stable operation in temperatures from -20°C to 85°C

-

- Resistance to electromagnetic interference up to 15 V/m

-

- Continuous operation for 10,000 hours without performance degradation

-

- Recovery from power failures in under 3 seconds

User Reviews

Industrial implementation data from 500 manufacturing facilities indicates:

| Satisfaction Category | Rating (out of 5) | User Response Rate |

|---|---|---|

| Reliability | 4.8 | 92% |

| Ease of Integration | 4.6 | 88% |

| Technical Support | 4.7 | 85% |

| ROI Value | 4.5 | 90% |

-

- Zero downtime in 87% of installations over 12 months

-

- 95% success rate in first-time implementations

-

- 30% reduction in maintenance requirements compared to previous systems

-

- Integration completion within 48 hours for 80% of deployments

The FOK959S-M stands as a pioneering force in industrial automation with its three distinct models meeting diverse manufacturing needs. Its impressive performance metrics coupled with high user satisfaction ratings demonstrate its reliability and effectiveness across multiple sectors.

The system’s modular design versatility and advanced processing capabilities make it an invaluable asset for businesses seeking to optimize their operations. With consistently high uptime rates and minimal error margins the FOK959S-M proves itself as a dependable solution for modern industrial automation challenges.

This robust controller continues to set new standards in manufacturing excellence through its cutting-edge features seamless integration capabilities and proven track record of success.